Service

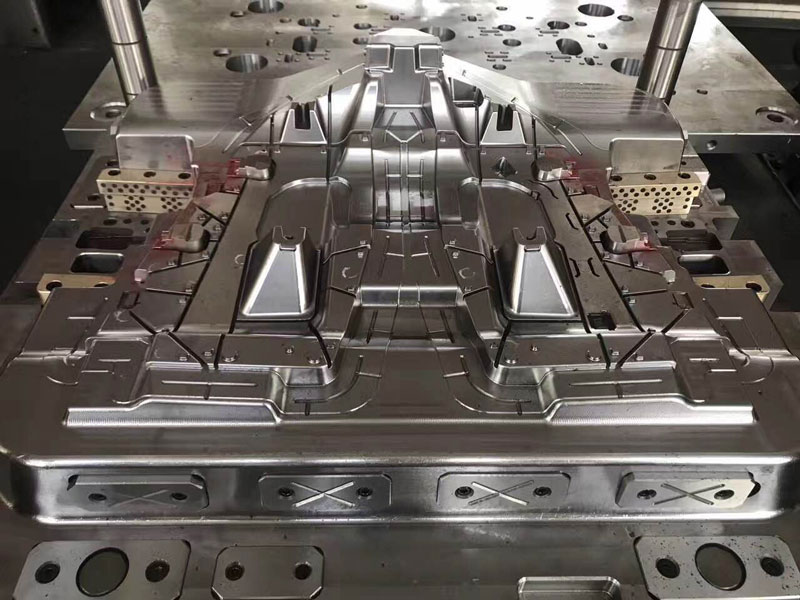

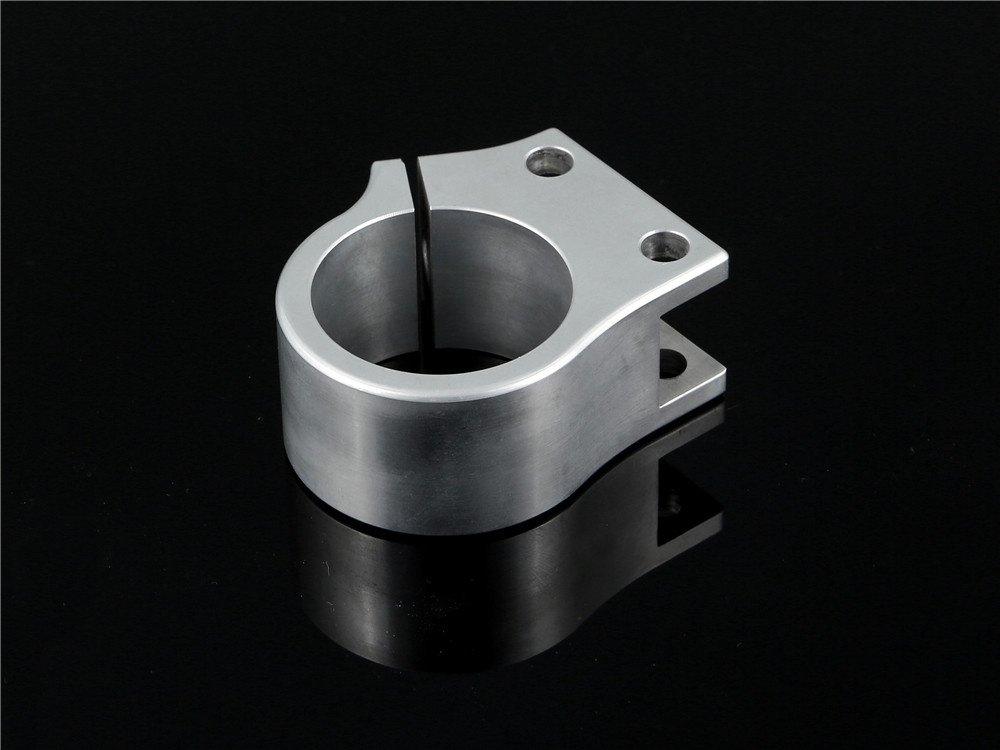

Rapid Tooling

Rapid Tooling Services

Rapid tooling is essentially a machining technique that is enabling you to quickly and cheaply get parts. Conceptually, it is any type of injection mold tooling, manufactured quickly, tested and validated of parts inexpensively before you invest in production tooling. Recently, most customers would like to consider selecting this method as the machining way due to its merits. As a full servicer of manufacturing, we take guarantee that a well management and high-quality standard service would be offered to customers.

Advantages of Rapid Tooling

It is acknowledged that the main reason people manufacture rapid tooling is for testing and validation of parts in the prototyping stages of new product development. Compared with other machining methods, rapid tooling owns its main advantages on its process and materials. Rapid tooling allows you to know how the parts will act in real-world applications and enable you to test and confirm you have made the correct material choices.

Besides that, fast production time and lower cost are the points that have triggered interested among the customers.

History

History of Rapid Tooling

The History of Rapid Tooling

Those who are familiar with rapid tooling get wise to rapid tooling starts in 90s of the last century. In order to find out the way that could build the molds in a matter of hours or days instead of weeks or months, they invented rapid tooling, which is simply, the creation of a mold in a shortened timeline.

Get Started

Start Your Next Project

Visit Us

A10 Building, Haosi Industrial Zone,

#165Nanpu Rd, Bao'an District,

Shenzhen, China.

Message Us

sales@rapid-cn.com

Get an Online Quote

Get a Quote